| Micele |

31 augustus 2020 19:35 |

Citaat:

Oorspronkelijk geplaatst door chris k

(Bericht 9435731)

Zelf maken is eigen personeel ...maar kan ook een onderaanneming zijn die in de ruimte van Tesla maakt

|

Bewijs het eens? Aha met werkkledij van Tesla dan. :lol:

Of weerleg de tekst en refertes in wikipedia met uw fantasiebronnen:

Citaat:

https://en.wikipedia.org/wiki/Tesla_Factory#Production

Tesla makes many parts itself, which is unusual in the auto business. Tesla also works with 300 suppliers around the world, of which 50 are in Northern California, and 10 in the San Francisco Bay Area.[91] Tesla's dashboard supplier SAS rents a 142,188-square-foot building near the factory, beginning in January 2017 with 200 employees.[92] Other suppliers to have opened facilities in the area to be close to Tesla include Eclipse Automation and Futuris Automotive Group.[93] Tesla produces many of its seats at its own seat factory a few miles south of the main factory.[94]

https://cleantechnica.com/2019/04/22...ud-like-seats/

|

Hoe meer jij kunt zeveren over Tesla hoe meer waard ze worden.

Nog een bron: (had ik die niet al gegeven?)

Citaat:

https://cleantechnica.com/2019/04/27...-seat-factory/

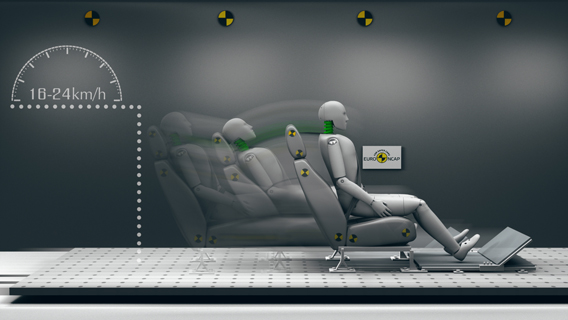

The factory where Tesla builds its seats may not sound exciting, but as probably the only automotive manufacturer that builds its own seats, we were enthused about our exclusive look into what is a very unique factory in the automotive industry. Tesla has not only brought seat manufacturing in-house. It has also applied the automation it has become known for in the industry to its seat factory. This automation has resulted in the most highly automated lower seat assembly in the automotive world, which you can see in our video below.

https://www.youtube.com/watch?v=ygys...ture=emb_title

Tesla was kind to pull back the curtain on its seat manufacturing operations, where we were able to get an inside look at the careful balance of automation and human-supported manufacturing that goes into the seats for its vehicles.

The seats that go into Tesla’s vehicles are not just any seats — they are world-class automotive seats that are assembled with vegan fabric that’s not only an adequate substitute for leather, but is actually superior in every noteworthy way. Tesla’s vegan leather seats, aesthetically beautiful (that’s a fact), are admirably durable, highly stain resistant, super soft, and (of course) greener than the norm.

Our video above provides a unique insight into the technology Tesla applies to the seats that it puts into its vehicles. That said, while the seats are important to a select few parts of your body, they are not even close to the most technologically advanced parts of the car. Just wait until we dig into Tesla’s Autopilot hardware and battery management systems. That’s when it gets really exciting. You can start to see the future through the possibilities of each technology individually and more so collectively as part of the whole car.

|

In de twee links kun je duidelijk lezen dat dit door Tesla opgeleide mensen zijn, "elke seconde telt". Maar dat lees je natuurlijk niet.

Citaat:

While Elon Musk called the Model 3 production process a “game of pennies” on the last conference call with the press, one of the engineers I spoke to called it a “game of seconds.” That’s how they look at it.

It’s one thing after another like this. That portion of the line is the only such seat production process in the world using the robots it uses — the first fully automated seat cushion production line in the world.

In another area, Tesla is using cutting-edge remote laser welding technology and other scrappy solutions to optimize the production system (i.e., to reduce production time). Some of the solutions go beyond the default process. Some areas of the seat factory are highly automated while others have the important touch of humans who are thoroughly trained in the company’s seat production dojo. (Seriously.) These employees are taken care of via thoughtful ergonomic systems and scheduling patterns. (Side note: I predict that some of them will move on to become world-class massage therapists.)

The production lines are highly flexible and can quite rapidly alternate which color seats are needed. There are slight differences in seat regulations across continents as well, but Tesla is again able to shift from one seat design to another.

The crew at the factory has squeezed much higher production volumes out of the initial Model 3 seat line than initially expected. The goal was originally 5,000 a week, but they now have the comfortable capability to produce a rate of 7,000 Model 3 seats per week — and the team has proven they can do more than that in one week with the existing line. That shows how much Tesla’s scrappy engineers and production optimizations have been customizing default systems in order to improve capital efficiency. The same equipment can now be used to produce a lot more product than initially expected, which means a lot more money for the same capital investment.

There’s space in the factory to add another seat production line, which could in theory double the current capabilities. Let that sink in for a moment. That’s a 40% or greater improvement compared to what was initially expected at the factory. Imagine you have a complicated lemonade machine that you thought could produce 10,000 cups of lemonade a day but can actually now produce 14,000 cups of lemonade.

At the end of the tour, one of the guides enthusiastically — with genuine excitement and joy in his eyes and voice — said the seat production facility was second to none across the world. He was certain about it, and super happy at what they had achieved. I thanked him and others for their service to society. After all, the goal of Tesla is not to simply create marshmallow seats for humans to sit on, and it’s not to make money for money’s sake. Tesla has a mission beyond that, which is infused in the workforce from top to bottom (surely not every employee, but definitely many of the people we talked to). Tesla is a mission-driven company that is trying to accelerate the transition to sustainable energy, because the future of human society relies heavily on our ability to do that. Society is facing an existential crisis, and Tesla is one of those companies trying to wake up the beast of public awareness and upgrade daily technology in order to avert the worst of that crisis.

Circling back to another company policy that Kyle and I will discuss in other articles, Tesla still operates in some startup-like ways. Elon encourages engineers to take risks if there’s a moderate (~60%) chance of success and improvement. This enables — or stimulates — the scrappy solutions employees find throughout the system. It stimulates the kind of changes that lead to a 60% improvement in the production capacity of a line. It is the kind of thing that leads to retiring CFO Deepak Ahuja emphasizing on at least two Tesla conference calls that Tesla is extremely capital efficient, more so than any other automaker he has worked for. I noticed him light up on two conference calls in recent years while trying to explain that, while trying to explain in just a couple of lines what numerous engineers are doing every day under Elon’s guidance to try to make Tesla not just a gold medalist, but the absolute best at what it does. The goal may not be perfection, but it’s to get as close to perfection as possible as quickly as possible.

|

|