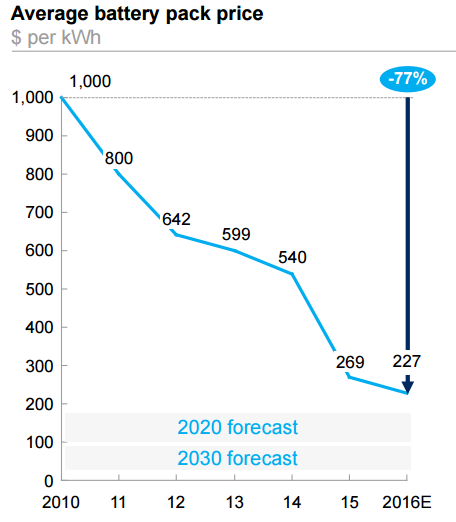

Gemiddelde batterijpack/powerpack prijzen, evolutie en toekomst:

Tesla (en mss bepaalde #Aziaten) heeft dankzij Gigafactory minstens 5 jaar voorsprong, wie weet 10 jaar.

Vandaag haalt Tesla zowat $ 130/kWh met zijn nieuwe 2170 batterijpacks. In 2016 - zonder Gigafactory - zat Tesla- (Panasonic-import) reeds onder $ 190/kwh vandaag doen ze minstens 30% beter. Vermoedelijk gaat Tesla in 2020 onder de $100/KWh gaan. Tussen een batterijpack of powerwall of powerpack zijn nog verschillen zeker wat betreft extra gewicht en navenante koeling-verwarming, ook zwaarte omvormer enz.... Batterijpack voor een wagen zullen de grootste eisen hebben en dito management. De prijzen zijn voor auto batterijpacks. Of moderne tractiebatterijpacks.

Citaat:

Tesla is among the automakers staying ahead of the trend. While McKinsey projects that battery pack prices will be below $190/kWh by the end of the decade, Tesla claims to be below $190/kWh since early 2016.

That’s how the automaker manages to achieve close to 30% gross margin on its flagship electric sedan, the Model S.

Though the Model S has a starting price of $68,000 and battery costs need to fall again in order to allow a starting price of $35,000, like for the upcoming Model 3.

Tesla aims to reduce the price of its batteries by another 30% ahead of the Model 3 with the new 2170 cells in production at the Gigafactory in Nevada.

It should enable a $35,000 price tag for a vehicle with a range of over 200 miles, but McKinsey sees $100/kWh as the target for ” true price parity with ICE vehicles (without incentives)”:

Given current system costs and pricing ability within certain segments, companies that offer EVs face the near-term prospect of losing money with each sale. Under a range of scenarios for future battery cost reductions, cars in the C/D segment in the US might not reach true price parity with ICE vehicles (without incentives) until between 2025 and 2030, when battery pack costs fall below $100/kWh, creating financial headwinds for automakers for the next two to three product cycles.

It matches the estimates of most battery manufacturers, but of course, Tesla is again pushing for a more aggressive timeline. CEO Elon Musk has previously hinted at a possibility of achieving a battery cost of $100 per kWh in 2020 – 5 to 10 years before most estimates.

https://electrek.co/2017/01/30/elect...-tesla-190kwh/

|

#

Citaat:

https://www.forbes.com/sites/bertels.../#444469fc6189

Jan 19, 2017, 02:49am

40% Price Drop On Chinese EV Batteries Spells Trouble For Tesla

A cornerstone of the Tesla story may be crumbling amid indications that the company's envisioned battery price advantage could evaporate long before the company's Gigafactory has gone into full swing. An analyst note from Morgan Stanley says that Chinese battery suppliers may cut their prices by 35%-40% in 2017, while still making a profit. On Thursday, shares of electric vehicle battery maker Samsung SDI dropped 4% on the news, while competitor LG Chem was down 1.8%. Tesla stock was unchanged in after-hours trading.

In the note cited by Barrons, Morgan Stanley analyst Shawn King said:

“According to Gaogong Industry Institute, some EV makers in China have proposed that battery vendors # cut prices by 35-40% in 2017. Our China analyst Jack Lu sees this proposal as likely to proceed, as some battery vendors in China could still make a decent profit after such a cut.”

Morgan Stanley sees this as negative for South Korean EV battery suppliers Samsung SDI and LG Chem, but any sharp price erosion on the battery front would imperil the viability of Tesla Motors’ Gigafactory in Reno, Nevada. The success of this undertaking depends on two factors: That Tesla is able to sell enough electric cars (along with a few stationary batteries they call powerwalls) to keep the ginormous factory busy. And on Tesla’s ability to make the batteries for less money than what’s offered by a supplier.

|

Tesla moet zich niet ongerust maken, het zijn de Europese ICE-constructeurs die zich moeten ongerust maken over hun nog niet afgewerkte batterijfabrieken. Zolang deze niet op eigen houtje hun batterijen in massaproductie gaan maken gaan de Aziaten met hun geld lopen... Of ze zetten zelf Aziatische batterijfabrieken in Europa met wslk nog Europese subsidies en deels gefinancieerd door de ICE-constructeurs...